In addition to the terrible human cost and the health challenge, the coronavirus outbreak is inflicting significant pain on the global economy.

From an Australian perspective, the near cessation in the movement

of people within and outside of China is having profound impacts on parts of

our education, tourism and import sectors.

The travel bans and mandatory quarantine measures put in place by the government in China appear to have had a significant impact in containing the spread of coronavirus. However, they have also severely impeded the flow of raw materials and goods throughout mainland China and prevented many people from returning to factories and other workplaces after the extended Chinese New Year holiday. Most severely affected by these restrictions are the well-known manufacturing hubs of Shanghai and Guangdong provinces.

Current situation

The Coronavirus continues to affect shipping volumes in and out of China. Although there are some indications that the situation is slowly improving in some areas with vessel operators cancelling or merging services fewer services.

New cases of the infection have slowed to single digits in the past few days in mainland China outside the Hubei province. This has prompted many local governments in low epidemic areas to encourage companies to allow employees to return to work by offering flexibility in working locations, as well as transportation or commuting assistance.

Additionally, the local Chinese governments are taking some financial measures to assist businesses in shipping orders. Further, some factories are even choosing to expedite their orders by Air Freight, even though this increases their costs by 200-300%.

China manufacturing – resuming normal programming

Most of the eastern provinces such as Zhejiang, Jiangsu, Fujian,

Guangdong, Shanghai, Shangdong are back to work. However, due to travel

restrictions, are still not operating normally due to staff shortages. Some of

the provinces have started using charter flights to get workers back to work.

Henan province has announced 16 March as the return to work date.

Most nationally owned manufacturers are currently at 80% productivity with logistics companies back at around 95%.

For example, in Guangdong, 99% of companies and manufacturers are back to work. However, productivity is still around 50%, expected to be 80% by mid/late March. Encouragingly, the top 300 Guangdong companies are running at 91% productivity. The province is using high-speed trains and charter flights to get workers back from inner Chinese provinces. The furniture industry in Guangdong is now back to 80% productivity.

The car parts industry in Shangdong province has been fully operational since 15 February under Government control.

The textile industry in Zhejiang province

is now also back to 80% productivity.

In Jiangsu province, 79% of companies and factories are back to work, and worker numbers are at 76% of the normal requirement.

The Chinese government is encouraging the use of trains to carry containers rather than rely on trucks between cities and provinces.

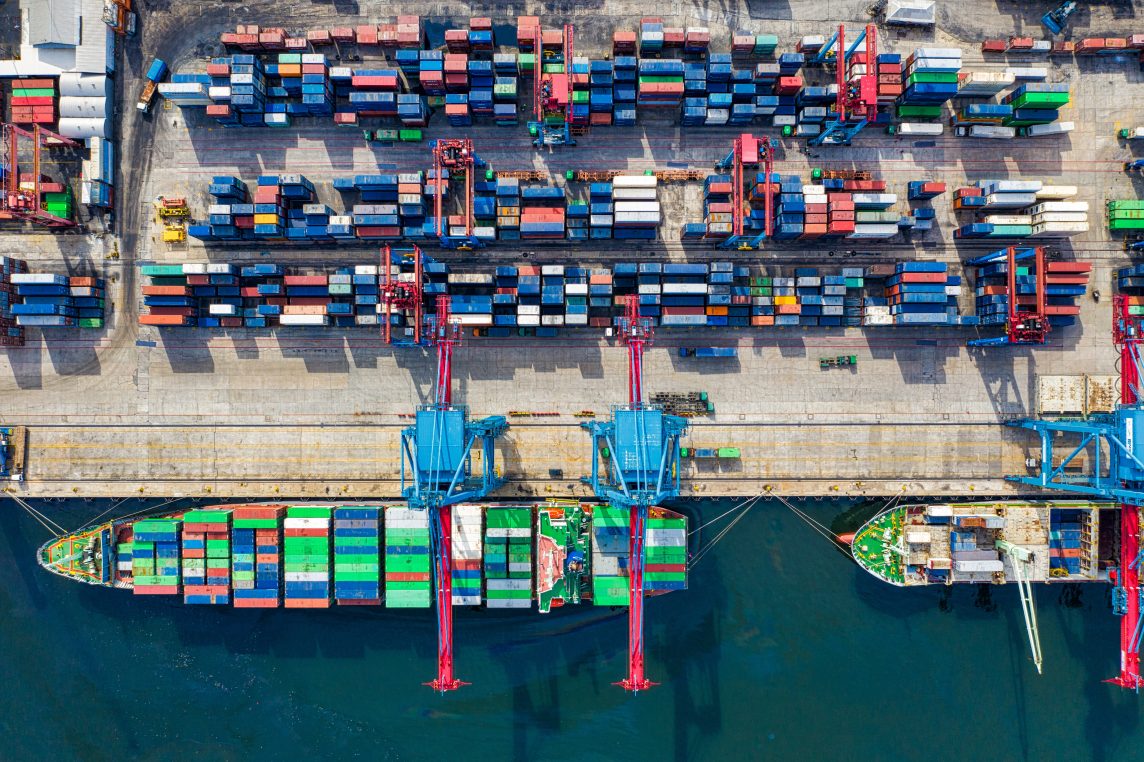

Sea freight

Based on our communication with shipping lines, most scheduled Australian trade will soon return to business as usual levels similar to pre-Chinese New Year volumes. We are expecting an uptick in sea freight bookings for March 2020 due to low retail inventories. As yet there is no significant pressure on space.

Air Freight, however, is a different story…

A lot of cargo originally booked for February for sea freight has been rebooked as Air Freight due to global inventory pressure.

Airlines including American, United, British Airways, and Qantas – have suspended all services from China, with many others reducing services until later in March. Because most air cargo is freighted on passenger craft this has caused significant capacity constraints and is likely to start pushing up rates once normal production resumes.

Apple products will resume shipping this weekend increasing demand from the electronics industry.

Magellan is a master loader throughout mainland China. This puts

us in an enviable position of influence with our major airline partners.

Magellan is currently facilitating daily uplifts utilising freighter services

in and out of China to ensure supply for our clients.

Where to from here?

Things are starting to look better. There are high stocks of export goods in storage that should be available to the supply chain as soon as the warehouse and transport facilities open back up. Additionally, the Chinese government is providing assistance throughout the supply chain to ensure a full return to economic stability is achieved as quickly as possible.

If the ongoing Coronavirus challenge has got you looking for alternatives and improvements to your supply chain logistics especially for Air Freight through this period, please get in touch with your local Magellan representative on 1300 651 888 to discuss strategies to assist during this period.

Links:

https://www.health.gov.au/health-topics/novel-coronavirus-2019-ncov